Mail Us: [email protected]

Call For Us: +86-13912347849

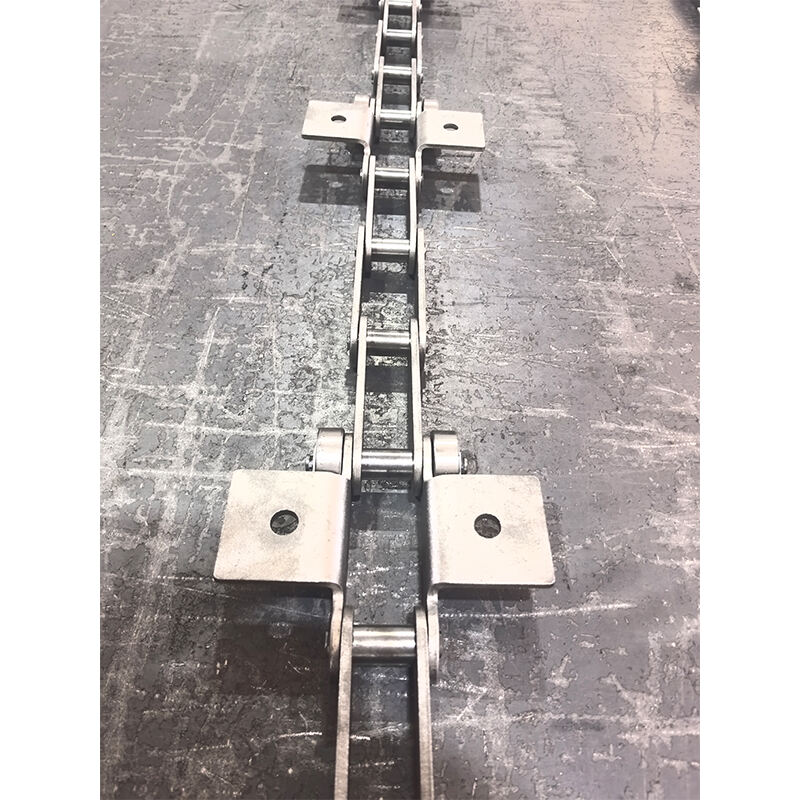

If you have found your way to our little blog, you are likely new to the fascinating world of conveyor chain drives — so welcome. And when it comes to these vital machinery, JINQIU CHAIN is a well-known name based on this planet. Conveyor chain drives are a very important part when it comes to factories and industries all over. It helps in faster movement of goods and materials from one place to other. They are like a massive conveyor belt that transports very heavy objects long distances over rough terrain. Conveyor chain drives are used in numerous applications across a vast array of industries, including automotive, food processing, packaging and even mining. Although many different variations of conveyor chain drives exist, as a rule the attached scheme is almost invariably similar. So being able to know each of these parts can help you see how they all play along one another. The primary components in conveyor chain drive systems are the chain, driven sprockets, bearings and shafts.

Roller Chain Drives- These are the most popular type of chain drives that you are going to see on conveyor systems. Which means they are freaking powerful & can haul some heavy *** with a few that will carry 15k lbs. Why Roller Chain Drives Are Used in Car Factories, Mining Operations and Paper Manufacturing We will discuss here on how to ensure that a conveyor chain drive system has an extended operational life. Maintaining it properly will make sure that it functions well and also, increasing its lifespan. However, here are some good ways to properly care for your conveyor chain drive system:

Dust, dirt and similar debris can accumulate on the chain and sprockets over time so also regular cleaning. This increases the wear and tear of the system leading to it becoming less effective over time. Tips: A good habit is to clean the chain and sprockets regularly to remove unwanted materials and increase effectiveness.

These require inspections similar to any other machine, conveyor chain drives need routine checks. Check the chain, sprockets, bearings and shafts frequently. Inspect for any wear and tear/sun damage/misalignment Early detection is speaking you can dodge an issue becoming an ordeal later on.

Conveyor chain drive technology is pretty exciting. Technological advancements such as automation, artificial intelligence, and the IoT are revolutionizing how factories run. And as brands pop up using this type of framework and sharing newest technology, it has the capacity to optimize operations, minimize downtime and be a protection in spots.

Jinqiu encompasses more than 60,000 square meter, has 8 production workshops with a combined production capacity of over 10,000 tons annually, 300 workers, 300 sets most advanced production and Conveyor chain drive.

Jinqiu Chain has Conveyor chain drive a range of products that are complex, including conveyor chain transmission chains, well as driving chains. The principal products are welded chain as well as palm oil chain and sugar chain. They are used numerous industries, including wood, palm, sugar as well as cement and metallurgy.

The engineering team, which includes more 50 engineers, continue developing chains specifically applications. They also provide solutions your needs. In the workshop, dynamism Conveyor chain drive team well as our experienced technicians will aid in achieving your goals.

We select highest quality alloy steel. We've developed complete quality control system and has been certified 9001:2015. The quality system monitors all aspects of the process, with main focus on prevention and the use of advanced testing equipment.The brand-new laser cutting machine and welding robots aid in create a beautiful appearance for chains.We guarantee 30 days delivery to the Conveyor chain drive order, for partners the consignment stock may reduce delivery time to speed up the turnover.JQ is a partner you can count on. Our 35 years of experience in supply chain management will not disappoint you.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved