Mail Us: [email protected]

Call For Us: +86-13912347849

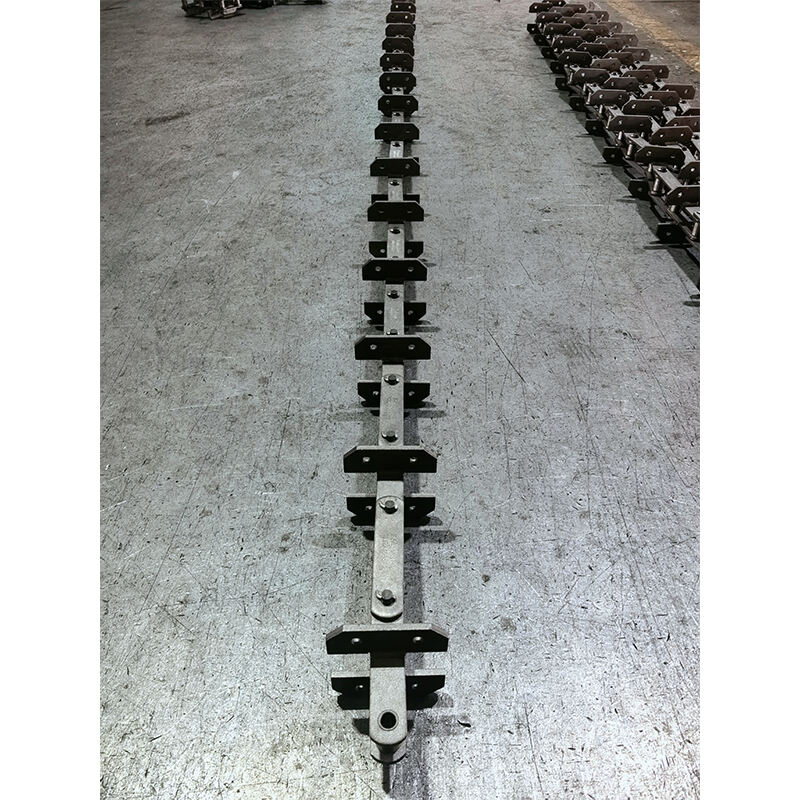

Ever wondered how things fly from here to there around the factories, warehouses? It’s pretty fascinating! Conveyor System is a machine used to transfer things from one place to other. Think of a belt that wraps around rollers or pulleys. This belt moves all sorts of stuff from product or shipping boxes, to bags with parts inside. This speeds up the transportation of these items and also does it in a more efficient manner, thanks to an overhead conveyor system. A chain sprocket by JINQIU CHAIN is like a wheel that connects the end of the conveyor belt to motor. The outer edge of the belt is toothed, enabling it to mesh with the links of a given conveyor chain. Imagine cement chain a bit like gears meshing together. When there is no sprocket to running the chain in a straight line, what could happen next is the chain could get off track which means it would then be unable to pull the conveyor belt. These risks are likely to result in delays and other concerns in the factory or logistics center.

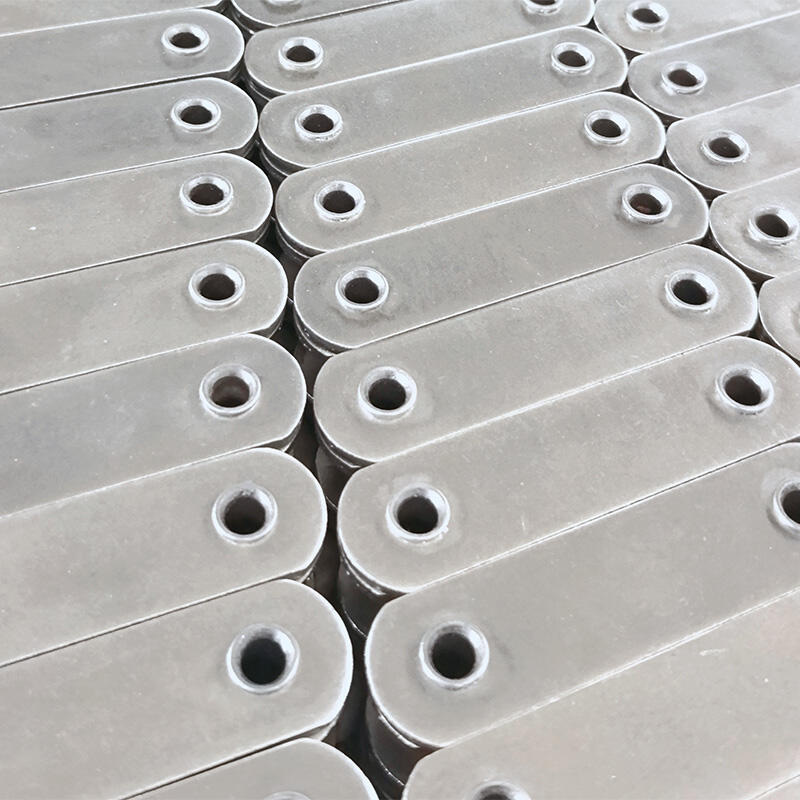

The diameter of the sprocket is measured by counting the distance between two rivets on a chain. This measurement is critical as it will determine how well the sprocket will fit with the chain. The hole size refers to the size of the hole in the center of the sprocket, which mates with that of a motor shaft. conveyor chain is essential because this should fit absolutely so that there will be functionality. More and fewer teeth around the sprocket faster or slower conveyor belt, respectively. Speed can vary (and more teeth is not necessarily a good thing if you need speed and power). The material of the sprocket of also plays a vital role. It is these different materials that make the sprocket last longer and wear better more than any difference in wear due to the difference in gears. We manufacture various types of conveyor chain sprockets at our JINQIU CHAIN. We produce sprockets by using finest materials like carbon steel, stainless steel and nylon. They come in multiple chain sizes, so finding the right fit is easier for you.

The conveyor system, and its chain sprockets of JINQIU CHAIN as part of it being machine requires thorough attention to serve for a longer time. Failing to address the sprockets can result in expensive repairs or downtime, and potentially hazardous conditions for workers. But taking care of your garden the cast chain way you take care of other things makes all the difference.

Common maintenance needs for this machine involve, cleaning the sprockets, lubrication of the smaller chains to keep them working correctly, regular checks and potential change of parts and most of all changing the sprockets and chains when necessary. While not as visually exciting, cleaning is chain bucket elevator also very helpful in ridding your chain of the dirt and other things that rub against each other and causing wear. Putting oil on the parts helps these constituents moved smoothly. If you find any of these teeth or chains are wearing out but then make sure to replace those. If not, the chain will slip out of track, rupture or lose longevity which is not good for a well running conveyor system.

Drive sprockets typically have just one set of teeth and are used in lighter work or at lower speeds. Now they are excellent for low power, simple applications. Duplex Sprockets - These types of bucket conveyor chain sprockets come with two set of teeth and are used for heavier jobs that require more strength and pace. Triplex sprockets have three teeth sets and are used in heavy-duty applications. Finally, the idler sprockets are connected to the motor in another way. Instead, they serve as the means for which to steer and balance the chain and prevent it from over-tensioning while providing a longer life.

We only use best quality alloy Conveyor chain sprocket. We have a complete system for quality assurance are certified according to 9001:2015. The entire process is governed by the quality system, with a particular focus on prevention. We use advanced testing equipment.The laser cutting machine along with welding robots can help give an ideal appearance for the chains.We may reduce the delivery period to 30 days consignment stock is low.JQ is a trusted partner that you can trust. The 35 years of our experience in supply chain management won't let you down.

Jinqiu encompasses more than 60,000 square meter, has 8 production workshops with a combined production capacity of over 10,000 tons annually, 300 workers, 300 sets most advanced production and Conveyor chain sprocket.

Jinqiu Chain has Conveyor chain sprocket a range of products that are complex, including conveyor chain transmission chains, well as driving chains. The principal products are welded chain as well as palm oil chain and sugar chain. They are used numerous industries, including wood, palm, sugar as well as cement and metallurgy.

More 50 engineers committed Conveyor chain sprocket chains meet your specific needs. In workshop, our dynamic management team and experienced technicians will aid in achieving this.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved