Mail Us: [email protected]

Call For Us: +86-13912347849

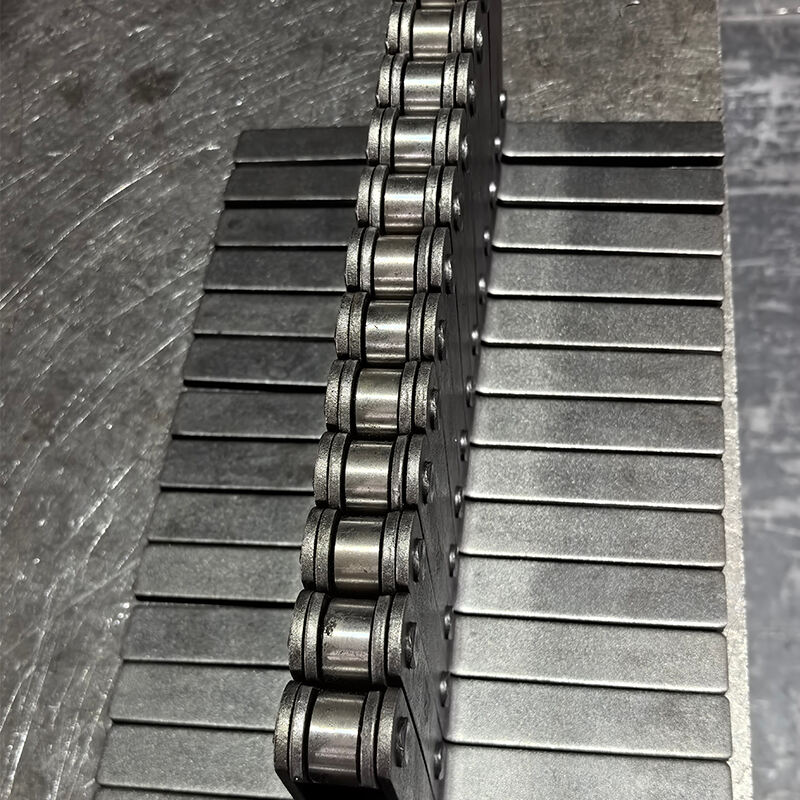

There are thousands of factories in Mexico that produce cars, clothes, and food. These factories have special machines to help move the parts around. These chains are typically known as conveyor chains and sprockets and are an essential part of these machines. These components allow machines to run effectively, and so the workers can manufacture as fast as possible. In Mexico's factories, chain conveyor roller and sprockets are very important in the production process. They transport heavy objects from one location to another. In factories, these chains and sprockets are used to transport parts of products along a production line. In a car factory, for instance, the conveyor chains and sprockets move car doors and wheels from one area to another. This allows workers to produce items more quickly

Factories have reasons to use conveyor chains and sprockets. And one important factor is that they save time and energy. This saves workers from lifting heavy parts as the conveyor chains and sprockets do the physical labour. It allows workers to concentrate on other crucial tasks, such as assembling the products. Consider what you are manufacturing and what your factory looks like to choose the best conveyor chain types and sprockets for your factory in Mexico. There are a variety of conveyor chains and sprockets that can be made for different jobs, and you need to pick which ones will work best for you.

An anchor conveyor chain sprockets with a drive wheel in a Mexican warehouse They move goods quickly, which in turn establishes faster order fulfillment. This is super important for things like online shopping, where customers demand rapid item arrival.

This, in turn, helps reduce errors in the warehouse. There is less chance for conveyor chain manufacturers to go missing or break when products are moving automatically. Makes it easier to keep track of the things and makes the working of the warehouse smoother.

In summary, there are promising prospects that advances in technology will enhance conveyor chains in Mexico. Chains and sprockets, nevertheless, have evolved from their primitive foundations. For instance, smart conveyor chains are being built that allow for communication with other machines within the manufacturing plant, which in turn helps everything work even better.

Jinqiu Conveyor chains and sprockets Mexico has come up with a variety of highly complex products that include conveyor chains, transmission chains, and driving chains. The primary products are welded chains and palm oil chain, sugar chain, cement chain, engineering chain and more. They used extensively fields of wood, palm oil, sugar cement, metallurgy construction machinery, and in other sectors.

Jinqiu Conveyor chains and sprockets Mexico more than 60,000 square feet with 8 production facilities which combined capacity more than 10,000 tonnes annually, 300 workers and more than 300 sets of advanced manufacturing and test equipment.

We utilize only finest quality alloy steels. We have a comprehensive system of quality control and are certified to 9001-2015. The quality system controls all aspects of the process, with a main focus on prevention and the use with the latest testing equipment.The brand-new laser cutting machine welding robots help to create a beautiful appearance for chains.For our partners, we cut the delivery time down to 30 days if the consignment inventory is not sufficient.JQ is a trusted partner that you can trust. The 35 years our Conveyor chains and sprockets Mexico in supply-chain management will not let you down.

The engineering team, comprising more 50 engineers, continue designing chains for special applications offer solutions that cater your demands. Our team dynamic managers with experienced technicians skilled workers will be able to help you realize that which is in the Conveyor chains and sprockets Mexico.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved