Mail Us: [email protected]

Call For Us: +86-13912347849

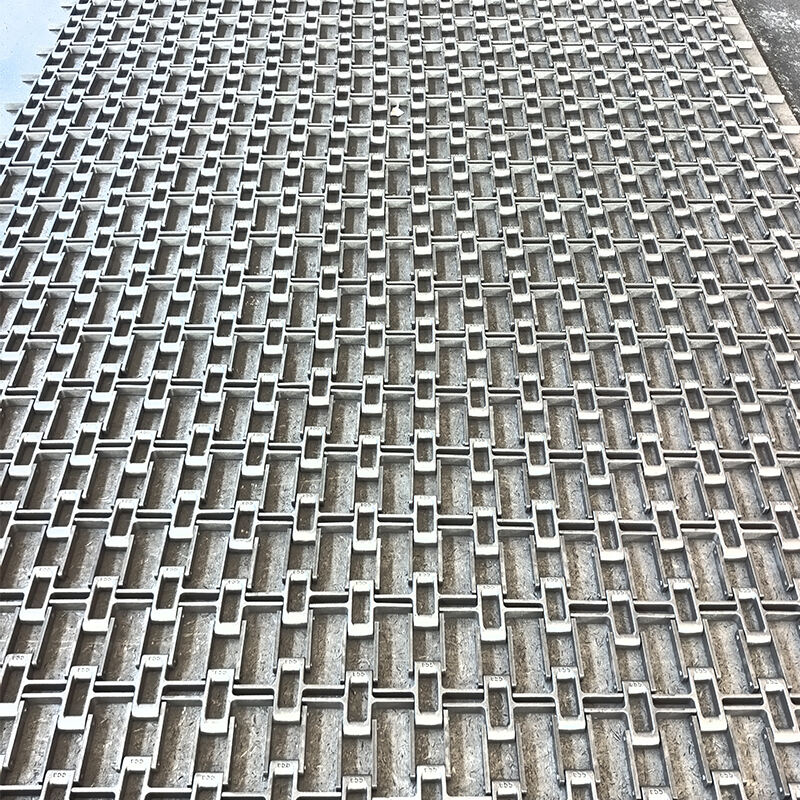

Paused in the moment as the conveyor chain spins in a mysterious dance in a factory, you will learn that this piece works a lot behind the scenes to make things move from point A to point B. In a wide range of tasks, conveyor chains are used to transport items such as boxes, components and also food products. A powder coating conveyor chain is one type of conveyor chain that is commonly found in such settings. These chains are uniquely designed to provide optimum strength and stability, which is a crucial factor given they have to bear heavy loads. In this article we will discuss what powder coating conveyor chains can do, how they can keep factories running high performance and smooth, how they can save on cost saving over time, why they are the best option for industries and understand the significance of them in the overall smooth operations of a factory

Powder coating of conveyor chains has many advantages. That is to say they do not need to be replaced as frequently, saving both time and money for the factory. Moreover, these chains also have chemicals and harsh substances which can destroy regular chains. That makes them great for work where those harsh conditions are common. Furthermore, powder coating conveyor chains are also easy to clean and maintain, thus ensures that they can operate without issues for a long period ofเวลาที่. These features make them an ideal solution for factories that want to work flat out.

Unlike general chains, powder coating drag conveyor chain can perform with increased efficiency. That means they can assist in getting things moved quickly and easily. When items can relay swiftly, the factories make extra in less time. This improves productivity and allows factories to meet their production schedules and keeps their customers happy. A factory that can manufacture products faster can also respond better to customer demand. In addition, due to their strength and durability, the likelihood of breakdowns and delays caused by system faults is decreased, which will cause production stops. The reliability required is a must for factory operations to run smoothly.

Although powder coated conveyor slat chains have a higher initial cost than standard chains, they can potentially save a significant amount of money in the long run. These chains are designed to last longer and need less maintenance which ultimately reduces the production costs of a factory. It can save factories a great deal of money on repairs and replacements that can accumulate into a penny-saving account for the lives of factories. In addition, powder coating conveyor chains are very efficient, meaning they allow factories to produce more products, and therefore use them to earn more income. Powder coat conveyor chain can provide these savings and more, improving overall performance in the factory.

For industries that require chains with high quality with durability and reliability, powder coating conveyor chains are known to be one of the best choices. They are also resistant to wear and tear, chemicals and other abrasive materials, which makes them suitable for a range of applications. Also, they help bring efficiency and cost-effect savings in the long run, so they are a careful investment, for the factories that want to upgrade their systems. Factory operations need to run continuously without unexpected interruptions and powder coating conveyor chains prove to be the solution for such reliable operations.

Regular operation of the factory is very beneficial for industries to be successful. One of the important components to ensure that everything works in a smooth and efficient way is the powder coating conveyor chains. They serve as a dependable method of transferring goods from one point to another, ensuring the continuation of production and avoiding any potential impact. They can be trusted to deliver day in and day out because these chains are durable and wear-resistant. As a conclusion, a manufacturer cannot stand without having a proper powder coating conveyor chains.

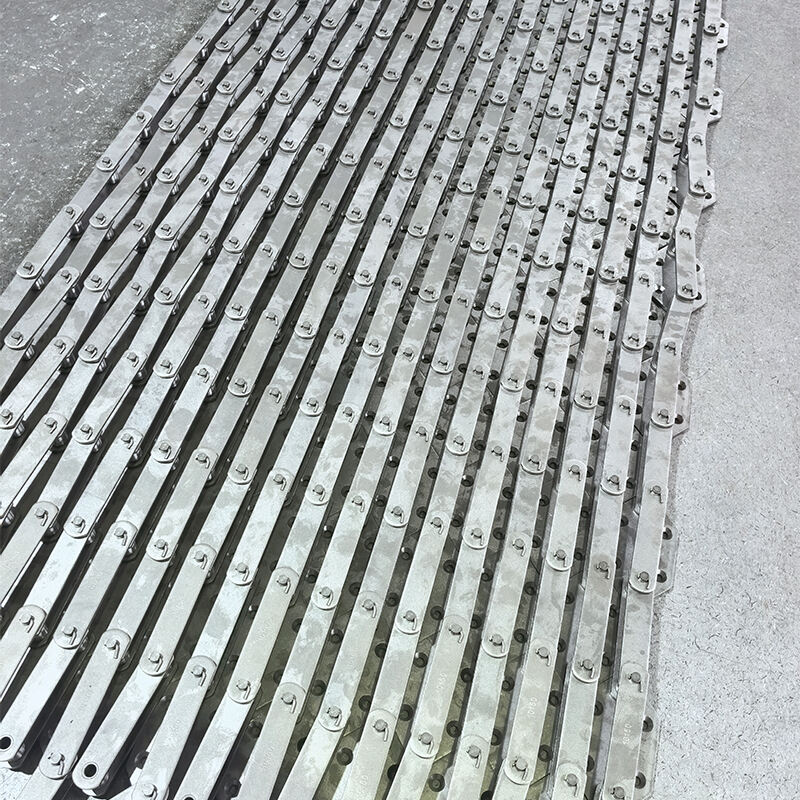

Powder coating conveyor chain home more 60,000 square metres includes 8 specially-designed production workshops, 300 staffs production capacity over 10,000 tons, over 300 sets modern manufacturing equipment well as testing equipment.

We select highest quality alloy steel. We have developed a complete quality control system and has been certified 9001:2015. The quality system controls every step the process with an emphasis on the prevention and use of the most advanced testing equipment.The latest laser cutting machine welding robots are able to give a stunning appearance to the chains.We guarantee 30 days delivery time orders that are ordinarily placed Partners, consignment stock may reduce delivery times to Powder coating conveyor chain the turnover.With our experience of 35 years in supply chain management JQ will a reliable supplier and will never fail to please you.

Jinqiu chain has designed a diverse product family that includes conveyor chain, transmission chain, driving chain. principal products are chains that welded well as sugar chain and palm oil chain. They used extensively industries such wood, palm oil, sugar, cement, metallurgy, Powder coating conveyor chain, and many other fields.

Over 50 engineers committed creating chains that satisfy specific needs. Our Powder coating conveyor chain of dynamic managers experienced technicians and skilled employees aid in achieving what you need in your workshop.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved