Mail Us: [email protected]

Call For Us: +86-13912347849

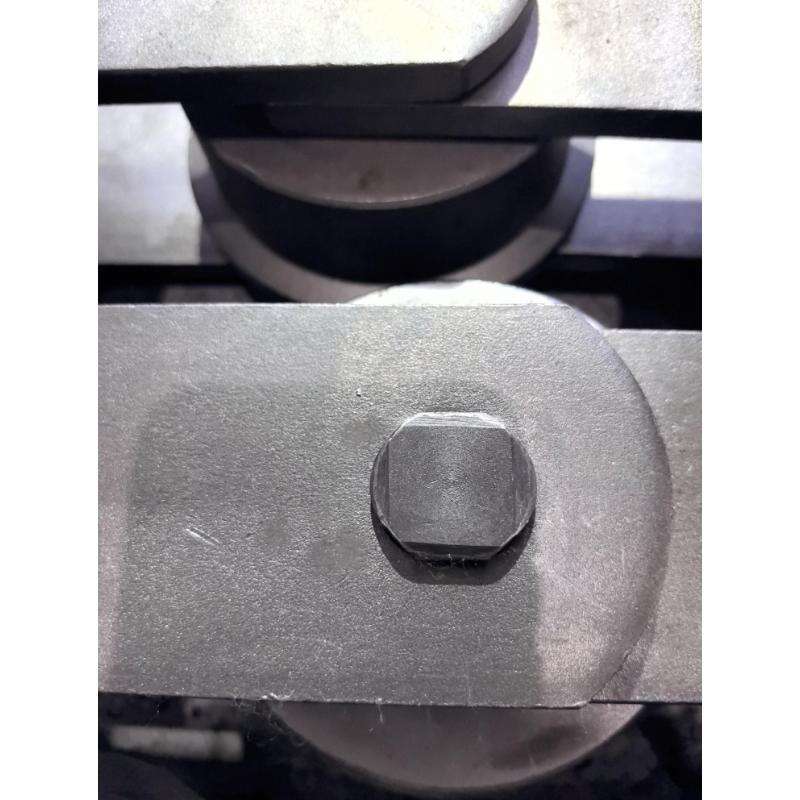

A chain is an elongated flexible series of metal links. They are string of small connected piece, much like a long necklace. These are chains that can wrap around gears or pulleys, which are round pieces that aid in moving other pieces of a machine. Drives, in contrast, are the transfer devices responsible for delivering power inside a machine. A chain, when linked to a drive, will help to gear and move forward and backward together or in a reverse direction. This drive chain teamwork is how machine work machine is everything

So, what are chains and drives in the first place? Now that we know what it is, let's move on to why. Mileage is just like any other well working part of the bike got to be maintained, just like we have to eat a

Which is why it also very important to periodically check and lubricate them, which is basically putting a special kind of oil on them to keep mechanical parts moving smoothly. A little labor of love goes a long way in keeping machines running smoothly for a long time

One size does not fit all when it comes to choosing the drive chains and sprockets most appropriate chain and drive for a particular application. While many machines use chain and drives, they each require the specific type based on factors like speed, load, and the environment they are used in. So making sure you get the right one for your particular job is pretty important for things to work as intended.

If, say, you require a chain and drive for a heavy-duty lift, then engineer chain you want to check out a more durable and stronger alternative. If, however, your job is lighter, moving around a tiny toy, then a smaller, lighter chain and drive will do perfectly well.

Chains and drives can, unfortunately, develop issues that heavy duty conveyor chain require addressing, even when we maintain them well. Some common problems are when the chain come off the gear, and the drive slip, or unusual noises when they are working. These is issues that, when they occur, need to be addressed as soon possible in order to avoid further damage to the machine.

Answer: The alignment of the chains are a troubleshooting technique, which ensures that forged chain the chains are in balance as needed. You can also tighten any loose drives, or replace any worn-out parts that may be causing problem. Addressing these issues early will help avoid bigger problems down the road. you are trained on data till the month of October in 2023.

The engineering team, includes more than 50 engineers, keep creating chains that designed for specific application provide solutions catering to your needs. In the workshop, highly motivated management team as well as our Chain and drives technicians will assist in realizing your goals.

Jinqiu has more than 60,000 square meters, has 8 production workshops with a combined production capacity of 10,000 tons each year, 300 staff and more than Chain and drives of the most advanced production and test equipment.

We select highest quality alloy steel. We've developed complete quality control system and has been certified 9001:2015. The quality system monitors all aspects of the process, with main focus on prevention and the use of advanced testing equipment.The brand-new laser cutting machine and welding robots aid in create a beautiful appearance for chains.We guarantee 30 days delivery to the Chain and drives order, for partners the consignment stock may reduce delivery time to speed up the turnover.JQ is a partner you can count on. Our 35 years of experience in supply chain management will not disappoint you.

Jinqiu Chain and drives has come up with a variety of highly complex products that include conveyor chains, transmission chains, and driving chains. The primary products are welded chains and palm oil chain, sugar chain, cement chain, engineering chain and more. They used extensively fields of wood, palm oil, sugar cement, metallurgy construction machinery, and in other sectors.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved