Mail Us: [email protected]

Call For Us: +86-13912347849

Drive Chains and Sprockets: A Complete Guide

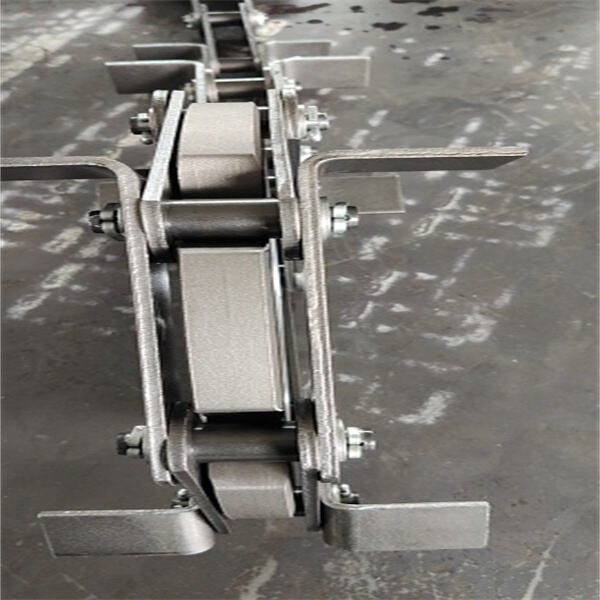

Drive chains and sprockets are essential components of modern industrial machinery, similar to the JINQIU CHAIN's product like engineer chain. These machines connect the power source, such as an engine or motor, to the output, such as a conveyor belt or wheel. They are used in a wide variety of applications, from farming and construction to manufacturing and transportation. We will discuss the advantages of using drive chains and sprockets, the latest innovations in this field, and how to ensure safety and quality while using them.

Drive chains and sprockets have several advantages over other power transmission systems such as belts, gears, and hydraulics, same with the drive chains and sprockets innovated by JINQIU CHAIN. Firstly, they offer high power transmission efficiency, which means that less power is lost as heat during the transfer process. This makes them ideal for heavy-duty applications where maximum power transfer is required.

Secondly, drive chains and sprockets are durable and reliable, even in harsh environmental conditions. They are resistant to dirt, dust, and corrosion, and can withstand high temperatures and pressures. This makes them ideal for use in agriculture, mining, and other industries where harsh environmental conditions are common.

In recent years, there has been significant innovation in the field of drive chains and sprockets. The focus has been on developing lightweight, high-strength materials and optimizing the design of these components for maximum efficiency and durability.

One example of innovation is the development of alternative materials such as carbon fiber and composite materials. These materials are very lightweight and have high strength, making them ideal for use in high-performance applications such as racing cars and sports motorcycles.

Another innovation is the development of tooth profile optimization techniques, also the JINQIU CHAIN's product such as sprocket. This technique optimizes the shape and size of the teeth on the sprocket to ensure maximum efficiency and minimal wear on the chain.

When using drive chains and sprockets, it is essential to ensure safety and quality. This involves regular inspection and maintenance of the components, using them within their intended limits, and following all safety guidelines and procedures.

One important aspect of safety is selecting the right type and size of drive chain and sprocket for the application, along with the drag conveyor chain produced by JINQIU CHAIN. Using too components small or weak can lead to failure and potentially dangerous situations. Similarly, too components large or powerful can be hard to control and may require specialized skills and training to operate safely.

Using drive chains and sprockets is relatively uncomplicated, the same as JINQIU CHAIN's WDH480 chain. The chain is wrapped around the sprocket, and the teeth of the sprocket engage with the links of the chain. Turning the sprocket causes the chain to move, transferring power from the source to the output.

One important aspect of using drive chains and sprockets is proper lubrication. Lubricating the chain and sprocket helps to reduce wear and tear, increase efficiency, and extend the life of the components. Different applications may require different types of lubrication, such as oil or grease, so it is important to consult the manufacturer's recommendations.

Jinqiu Chain has come up with a series of sophisticated products that include Drive chains and sprockets, transmission chains, and driving chains. Main products are welded chain and palm oil chain, sugar chain, cement chain engineering chain as well as other chains. They are widely used in industries like wood palm oil, sugar cement, metallurgy construction machinery, and many other fields.

The engineering team, includes more 50 engineers, constantly designing chains a specific application. We also offer solutions to needs. In our workshop, our highly motivated management team and skilled technicians will aid in Drive chains and sprockets this.

Jinqiu encompasses more than Drive chains and sprockets square metres, has 8 production workshops that have a combined capacity of over 10,000 tons annually, 300 workers and more than 300 sets in the latest productions test equipment.

We utilize only finest quality alloy steels. We have a comprehensive system of quality control and are certified to 9001-2015. The quality system controls all aspects of the process, with a main focus on prevention and the use with the latest testing equipment.The brand-new laser cutting machine welding robots help to create a beautiful appearance for chains.For our partners, we cut the delivery time down to 30 days if the consignment inventory is not sufficient.JQ is a trusted partner that you can trust. The 35 years our Drive chains and sprockets in supply-chain management will not let you down.

Regular inspection and maintenance are essential to ensure the safe and efficient operation of drive chains and sprockets. This includes cleaning and lubricating the components, inspecting for wear or damage, and replacing any worn or damaged components.

It is also important to follow the manufacturer's recommendations for service intervals, including replacing components such as chains and sprockets when they reach the end of their useful life, as well as the sprockets and chain made by JINQIU CHAIN. Failure to perform regular maintenance can result in reduced efficiency, increased wear and tear, and potentially dangerous situations.

Drive chains and sprockets are used in a wide variety of applications. They are commonly used in agriculture, construction, mining, and industrial manufacturing. For example, they are used to power conveyor belts, transport equipment, and heavy machinery.

They are also commonly used in sports equipment such as bicycles, motorcycles, and small aircraft. In these applications, they offer lightweight and high-strength power transmission, making them ideal for high-performance applications.

Drive chains and sprockets are essential components of modern industrial machinery, also the JINQIU CHAIN's product such as drag conveyor chain. They offer high power transmission efficiency, durability, and reliability. Innovations in materials and designs have led to improved performance and efficiency, and regular maintenance and following safety guidelines are essential to ensure safe and efficient operation. They are used in a wide variety of applications, from agriculture to transportation and sports equipment.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved