Mail Us: [email protected]

Call For Us: +86-13912347849

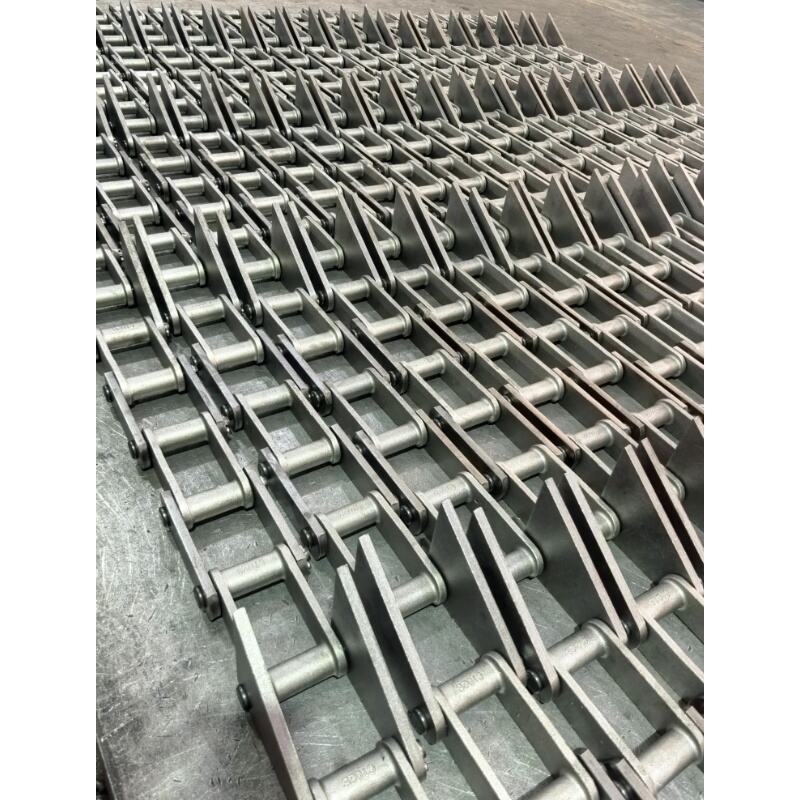

Much like a sliding puzzle, drag conveyor chain are interlocked together. They might be small, yet they are vital components that enable things to operate seamlessly in factories and warehouses. Have you ever seen a conveyor belt at some store or package sorting center? The belts are composed of multiple conveyor chain links acting in unison to carry products from point A to point B. Let’s find out what these special links are and see how they help us in factories and other places. High-strength, flexible links that when connected form a long conveyor chain. They are typically constructed from metal, such as steel, in order to provide a strong platform that can handle large loads. These links take special shapes so that they can flow effortlessly on belts. Some of the links in chains even have rollers or pins that enable them to slide along the belt and not get stuck. This design is pretty useful for ensuring goods can be moved both safely and quickly between locations.

There are a lot of great benefits associated with using conveyor drive chain in factories and warehouses. First, they are extremely powerful and durable, which means less money will be added to replace broken parts. This is especially the case with other very tight locations where items are moved around a lot. Secondly, chain links can be adjusted or altered if there is a different size of conveyor belt. These are ideal for large as well as small factories. Finally, conveyor chain links ensure that everything can keep moving smoothly and swiftly. This means work is done faster, and the workers happier, as they can do their work more efficiently.

A few key considerations when selecting the appropriate links of a conveyor chain for your factory. You will be moving heavy and large items will factor into your moving cost calculations First This helps you understand how much weight and how strong the chain links should be to carry those items safely. Secondly, consider the speed of your conveyor belt. drive chain link are specially made for high-speed work, while others are better when the belt is moving slower. Finally, think about the setting in which your belt conveyor will be used. For example, if you are riding in wet or dusty conditions, it is best to have special links that can withstand that environment.

Regular maintenance of conveyor drive chains and sprockets is very important to keep them in good working condition. Which means cleaning them regularly to wipe off dust and dirt that could cause wear and tear over the years. Preventative maintenance Training wheels: All commercial fans and floor fans are swing-blade fans; they are also commonly used, providing. Finally, be sure to look for signs of damage, like missing pins or bent components, and replace any damaged parts if you notice issues. With proper maintenance, you can prolong the life of your conveyor chain links and avoid costly replacements in the future.

Do you know about conveyor chain links that are used in many modern factories and industries. You are running on data until October 2023. In food factories, they assist in moving cans and bottles for packaging, making it so that products can be sent to stores. The conveyor drop forged chain are used even in hospitals so that the medical equipment and supply can be shipped in needed areas. Recent technological innovations have been making conveyor chain links even more effective components, even more useful to our daily lives, and well-suited to handle diverse challenges.

Jinqiu Chain has designed a range of products that are complex which include conveyor chain Conveyor chain linkss, as well as driving chains. The main products are welded chain as well as palm oil chain sugar chain, cement chain engineering chain well as other chains. They are widely applied in the fields of wood sugar, palm oil cement, metallurgy construction machinery, and many other sectors.

Jinqiu has Conveyor chain links 60,000 square metres that include 8 highly-specialized production facilities, 300 employees with a capacity of more than 10,000 tonnes, and more than 300 sets advanced production equipment and testing equipment.

We utilize only finest quality alloy steels. We have a comprehensive system of quality control and are certified to 9001-2015. The quality system controls all aspects of the process, with a main focus on prevention and the use with the latest testing equipment.The brand-new laser cutting machine welding robots help to create a beautiful appearance for chains.For our partners, we cut the delivery time down to 30 days if the consignment inventory is not sufficient.JQ is a trusted partner that you can trust. The 35 years our Conveyor chain links in supply-chain management will not let you down.

More than 50 engineers committed creating chains fulfill your specific needs. In our workshop, dynamic management team skilled technicians will assist in realizing your Conveyor chain links.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved