Mail Us: [email protected]

Call For Us: +86-13912347849

Driver Chain Theory

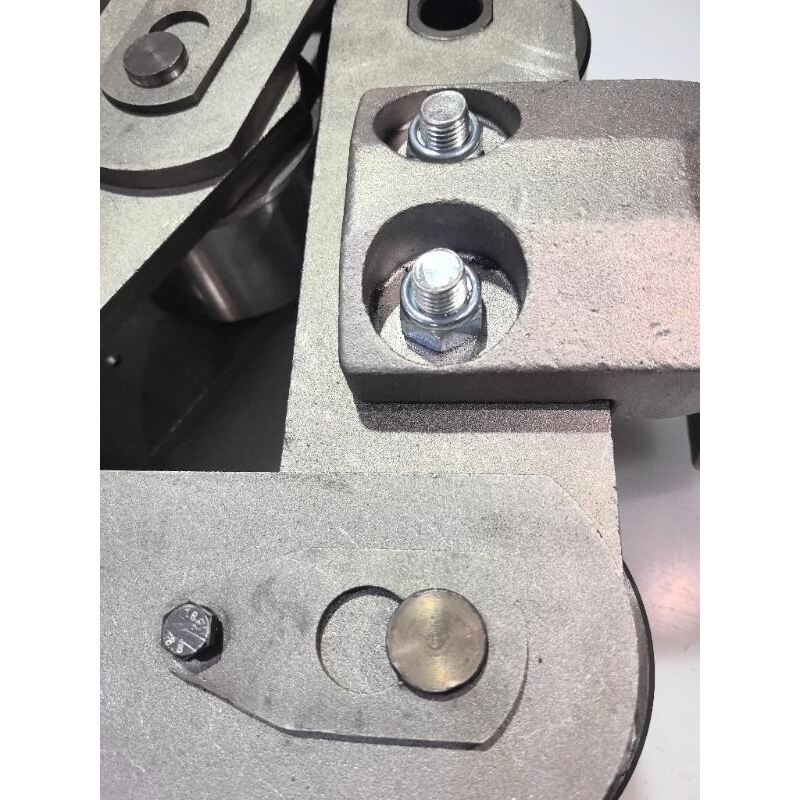

A driver chain is vital for most of the machines, and particularly in case of vehicles. Which functions to pivot the wheels and drive vehicle. These are several small components working in synchronization just to ensure smooth and fuel-efficient running of the vehicle. Chains, Sprockets, and Tensioners are the three primary components of a driver chain. These make a complete system. For instance, when you ride a bike the chain attaches to your sprockets which allows your wheels to turn and pushes you forward. Tensioners are unique components applied to keep the chain tight. This is vital as if the chain becomes too slack, it will result in issues with movement. Tensioners were used to make sure that the chain does not slip or fall.

If you want that the JINQIU CHAIN driver chain and drag conveyor chain lasts as much as possible and work well, then take care of it. One of the first things you could do, that would make a significant improvement to your way around an engine would be simply oiling the chain on occasion. Lubricating helps to eliminate creaks that are not only annoying but also remove dirt and grime from the chain as it accumulates. We must look after our toys too, keeping them clean and healthy for the longevity of their function. And do not forget to examine the slackness of the chain frequently. The chain can break during operation if it too tight. Alternatively, a chain too slack will not perform correctly and can reduce performance. Therefore, maintaining the correct chain tension is crucial for a better ride.

Different materials such as magnesium, kevlar or Aluminum can be used to create drive chain with each material offering it is own distinct advantages and disadvantages. Steel or stainless steel are common materials for driver chains. Steel: Among the strongest and most stable metal of them all. Further, there is nickel plated steel which does not rust or tarnish as easily and so could be a better option if the chain will often get wet. Alternatively, stainless steel is so famed for it is anti-rust properties that it thrives in the likes of damp or wet scenarios This means it is recognized that one has to select the right material for different sorts of vehicles. Some chains are designed for higher weight capacities and larger vehicles like trucks taxpayers carry; if locks heavier require stronger. The correct usage of the demanded materials, which guarantees longer functioning and more wearing out-free driver chain.

Keep the JINQIU CHAIN driver chain in good condition, this will make your car go faster as well. A well looked after chain is able to deliver power more efficiently, making you faster. It also helps to keep the sprockets neat and clean. Sprockets - They are the round wheels that make a track rack and move on chains, which helps power movement of vehicle, their design is critical for operation; Worn or broken sprockets can cause the chain to slip over it, rather than "kissing." This may result in a power loss and can lead to slower speeds than expected. The sprockets are essential components as well and should be examined periodically to maintain their performance. Maintaining the drive chain link and ensuring that it remains in top running order as well as keeping sprockets properly positioned will contribute to greater vehicle efficiency, speed control.

JINQIU CHAIN driver chains sometimes go wrong, then again a large portion of these issues are effortlessly settled. Loose and dirty chain is one of the common issues with this bike. A noisy chain can be a frustrating issue, either when you are riding your bike or driving any kind of motor vehicle. The cause of this noise is the chain as it runs over the cogs so you can cure a noisy drive chain by making sure your chain isn't too slack or give it wipe-over if it is mucky. If properly adjusted it will wear the chain, and eventually become sloppy backup. Should the chain go out of place far too much, it will not work effectively and can bring on added issues. In these incidents, it becomes necessary to replace the chain whenever required for optimal performance. By paying attention to these issues manually checking for them and performing maintenance, anyone can properly maintain their driver chain.

We select highest quality alloy steel. We have developed a complete quality control system and has been certified 9001:2015. The quality system controls every step the process with an emphasis on the prevention and use of the most advanced testing equipment.The latest laser cutting machine welding robots are able to give a stunning appearance to the chains.We guarantee 30 days delivery time orders that are ordinarily placed Partners, consignment stock may reduce delivery times to Driver chain the turnover.With our experience of 35 years in supply chain management JQ will a reliable supplier and will never fail to please you.

Jinqiu Chain has come up with a variety of highly complexDriver chain that include conveyor chains transmission chains, as well as driving chains most popular products include chains that are welded as well as palm oil chain and sugar chain. They are used extensively in industries like wood sugar, palm oil cement, metallurgy construction machinery and other industries.

The engineering team, comprising more 50 engineers, continue designing chains for special applications offer solutions that cater your demands. Our team dynamic managers with experienced technicians skilled workers will be able to help you realize that which is in the Driver chain.

Jinqiu encompasses more than Driver chain square metres, has 8 production workshops that have a combined capacity of over 10,000 tons annually, 300 workers and more than 300 sets in the latest productions test equipment.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved