Mail Us: [email protected]

Call For Us: +86-13912347849

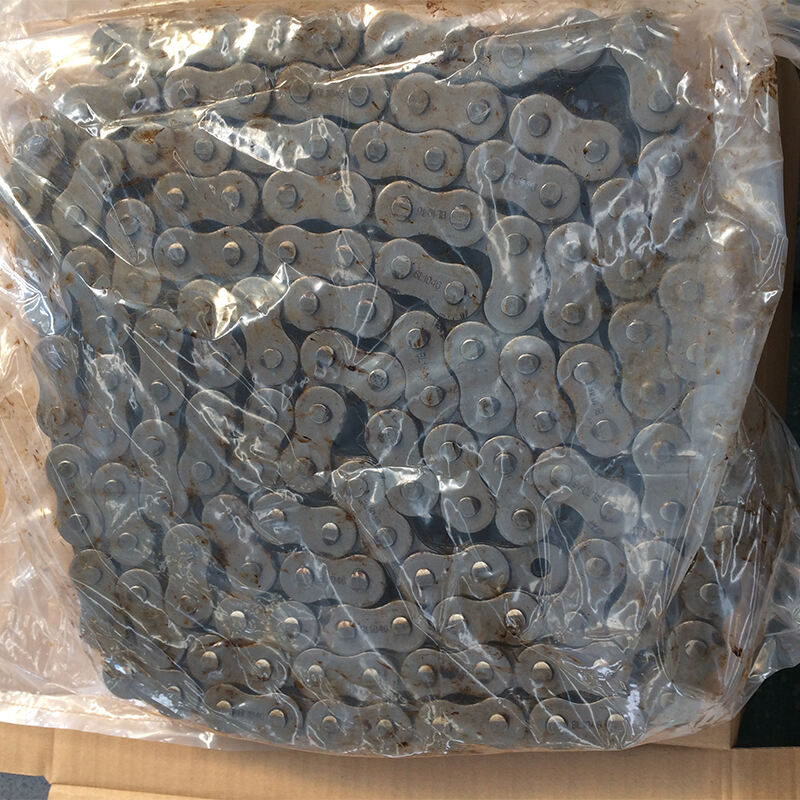

Chains and sprockets are two key components of a lot of the machines that people use. They help in transmitting power from one part of the machinery to another. So they contribute to the machine working as intended. A chain is a series of small metal parts which are joined to make an extended chain A sprocket is a circular wheel with teeth The output of the gear can rotate on this part for as much power as needed. These teeth mesh with the chain, not unlike how gears mesh together. As the sprocket turns, so does the chain, and in doing so it helps convey power from one part of the machine to another. The machine needs this movement to do it's job. How chains and sprockets are designed to operate influences how they are manufactured. For instance, if a machine gets heavy tasks like an enormous quantity of power, it should use the long chain along with large links, and the big sprockets also did work. The JINQIU CHAIN conveyor chains and sprockets able to withstand the force and stress that top end machinery churns out which would destroy smaller components. Conversely, if a machine must only provide delicate movements and accurate it will require a chain with very small links and a cog with many teeth. These smaller pieces are also what provide a finer control, something very necessary for tasks that need precision.

Chains and sprockets have been around forever used in countless machinery but technology has made them better as the years go by. These days they can often be found in tough items like stainless steel. This stuff make them longest and durable from the scratch. In addition, some chains and sprockets are coated with special materials to avoid rusting and oxidation loaders. The reason behind this is, this coating helps them to fine in rough situations and remains in order. What kind of chain the machine will accept and what size sprocket on the engine is used that it fit in your system. Choosing wisely on an electric scooter can save you money over time. Choose a chain and sprocket too weak for your application, and they will break or wear out too soon. This would make replacements necessary again and this will not be a cheap affair. On the other hand, if you opt for a chain and sprocket that are too large for your machine, it may function improperly or be too heavy which could result in issues.

There are several key factors you should consider when selecting your chain and sprocket. The first step is to determine what type of machine you have and how much power it requires for optimal performance. Next, JINQIU CHAIN drive chains and sprockets you want to learn how quickly the chain and also sprocket should be turning in order for the device to run properly. And lastly, you have to learn what size chain and sprocket your machine requires. Checking this out beforehand can make sure that you are choosing components which will best suit what you need.

Therefor, chains and sprockets must be well maintained so that they work properly and last long. Some simple suggestions are to maintain them -- clean. If the chain and sprocket are too dirty it make make them wear down faster than they should. Keeping them clean can help prevent this from happening. You also need to regularly oil or lubricant them. This will also aid in maintaining a continuously lubricated chain and sprocket, minimizing wear from the friction.

There are numerous industries and work wherein they use chains, in addition to sprockets too. For example, in the agricultural industry, they are in machines such as farm tractors and combines that assist farmers in their routine work. Chains and sprockets are common in the construction industry on heavy machinery, such as bulldozers and cranes. They use chains and sprockets to carry a bucket on a rope, which can lift and transport large amounts of material JINQIU CHAIN sprockets and chain important in factories because of their role on conveyors as well as packaging machines. With an example of these applications, it goes without saying how chains and sprockets are such a versatile and essential part in our daily lives.

Jinqiu covers more than 60,000 square feet, has 8 production workshops with a combined production capacity of over 10,000 tons annually, Industrial chains and sprockets as well as over 300 sets of modern manufacturing test equipments.

We select highest quality alloy steel. We've developed complete quality control system and has been certified 9001:2015. The quality system monitors all aspects of the process, with main focus on prevention and the use of advanced testing equipment.The brand-new laser cutting machine and welding robots aid in create a beautiful appearance for chains.We guarantee 30 days delivery to the Industrial chains and sprockets order, for partners the consignment stock may reduce delivery time to speed up the turnover.JQ is a partner you can count on. Our 35 years of experience in supply chain management will not disappoint you.

The engineering team, comprising more 50 engineers, keep Industrial chains and sprockets chains specifically application and provide solutions catering your needs. In our workshop, highly motivated management team as well as our experienced technicians will assist in realizing the goals.

Jinqiu Chain has come up with a family complex products, including conveyor chain transmission chains, as well as Industrial chains and sprockets. The principal products are welded chain as well as palm oil chain and sugar chain. They are widely applied in industries like wood palm oil, sugar cement, metallurgy construction machinery, and in other industries.

Copyright © Jiangsu Jinqiu Chain Transmission Co.,Ltd. All Rights Reserved